Standing seam metal roof emerges as a remarkable architectural choice, seamlessly blending durability with aesthetic appeal. This innovative roofing system boasts elevated seams that provide exceptional water resistance and longevity, setting it apart from conventional roofing materials. Crafted from a variety of metals, including steel and aluminium, standing seam roofs offer versatility in design while ensuring robust performance against the elements.

The construction intricacies of standing seam roofs contribute to their appeal, with a design that not only enhances the building’s silhouette but also facilitates efficient installation. With the added benefits of energy efficiency and reduced maintenance requirements, it’s no wonder that discerning builders and homeowners alike are opting for this modern solution to their roofing needs.

Overview of Standing Seam Metal Roofs

Standing seam metal roofs represent a contemporary choice in roofing, renowned for their durability and sleek aesthetics. Their characteristic design features raised seams that interlock panels, creating a visually appealing finish while also providing superior protection against the elements. This roofing style has gained significant traction in both residential and commercial sectors due to its long-lasting benefits and modern appeal.

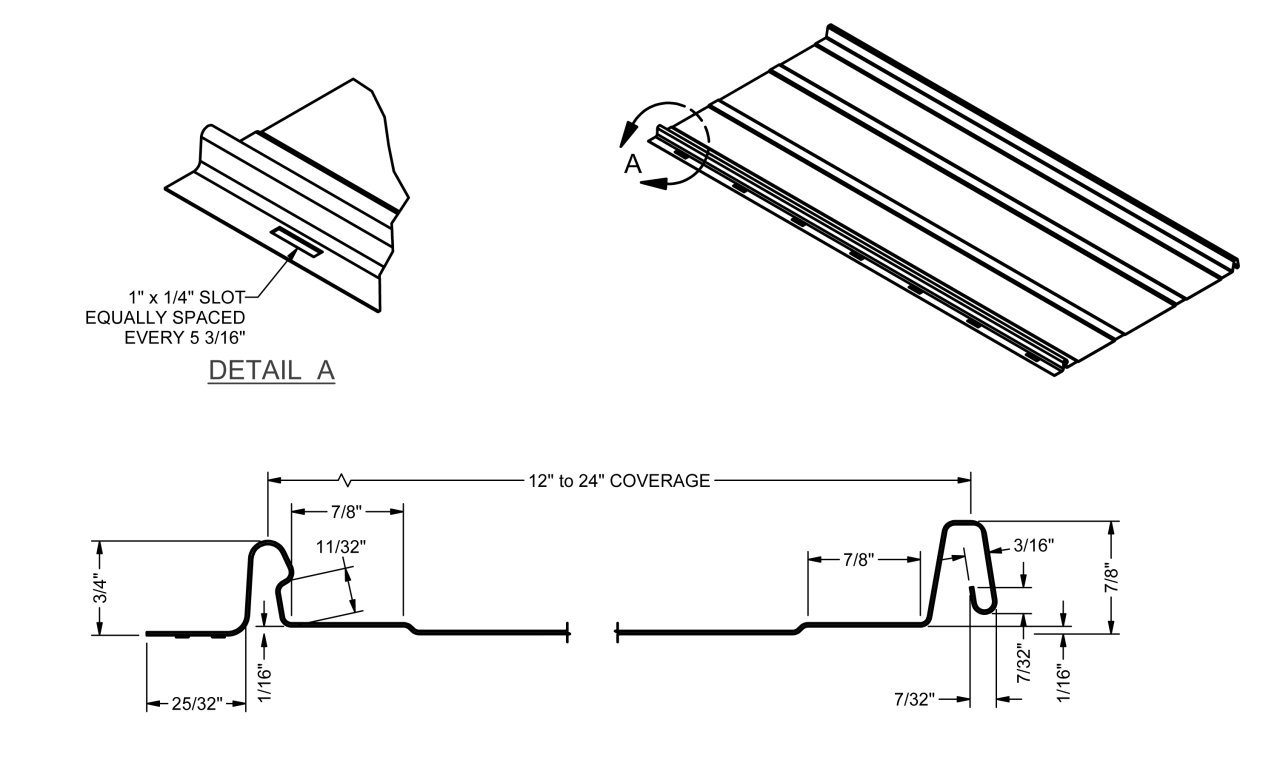

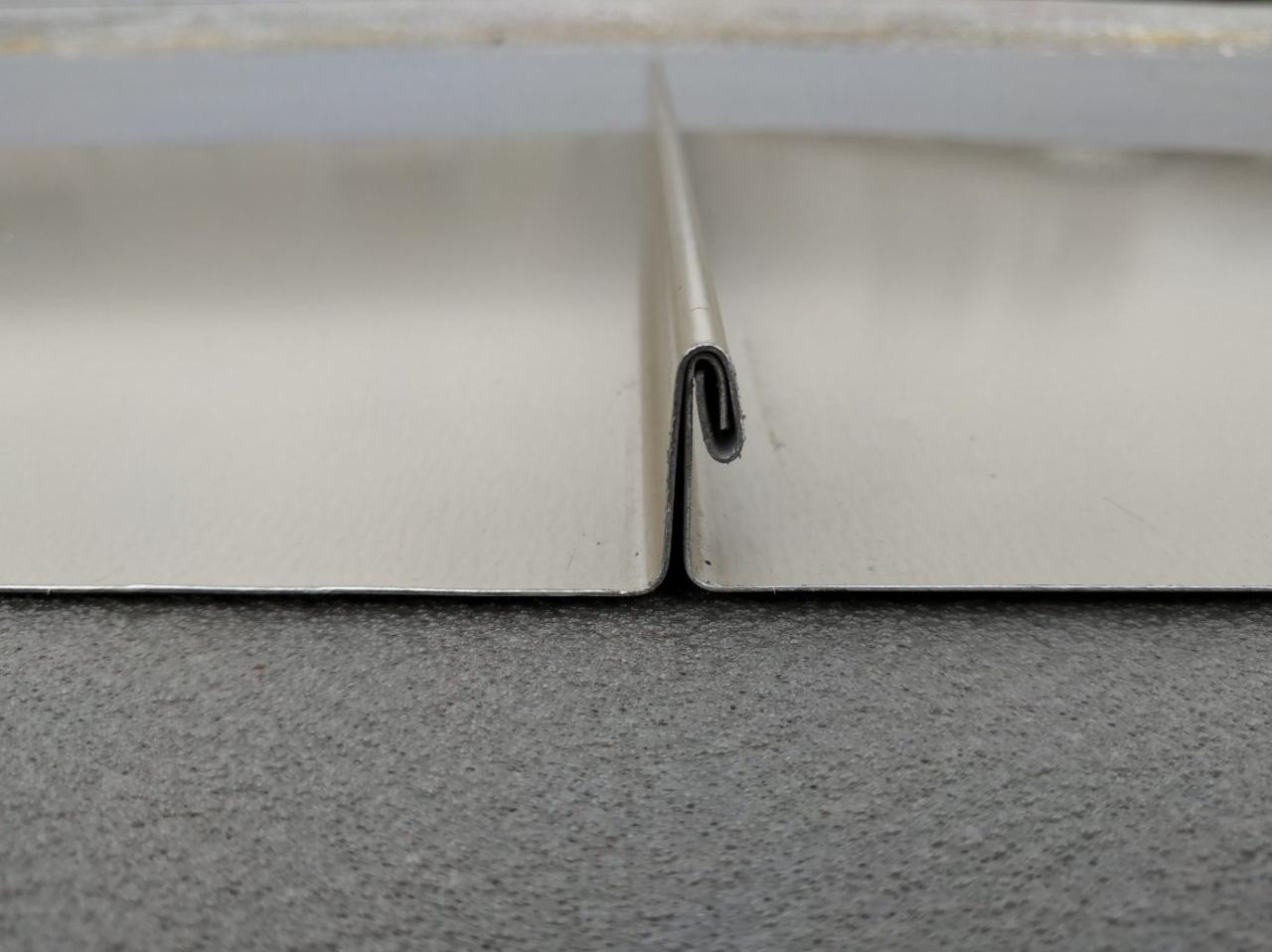

The construction of standing seam metal roofs involves several key design features that enhance their functionality. Typically, these roofs are made from interlocking panels that run vertically from the ridge to the eaves, with raised seams that create a watertight seal. The panels are usually secured to the roof deck using hidden fasteners, which not only contribute to the roof’s seamless appearance but also prevent water intrusion. The design allows for thermal expansion and contraction without compromising the roofing integrity, making it a practical option in varying climates.

Materials Used in Standing Seam Metal Roofing Systems

A variety of materials are employed in the fabrication of standing seam metal roofing systems, each offering unique benefits. The most common materials include:

- Galvalume Steel: This substrate combines steel’s strength with aluminium’s corrosion resistance, offering excellent durability and longevity.

- Aluminium: Lightweight and resistant to rust, aluminium is ideal for coastal regions prone to saltwater exposure.

- Copper: Revered for its aesthetic appeal, copper develops a distinctive patina over time, which can be a desirable feature in certain architectural styles.

- Zinc: Similar to copper, zinc provides a unique look and is known for its longevity and low maintenance requirements.

The choice of material can significantly influence the overall performance and aesthetic of the roofing. Each material caters to specific environmental conditions and design preferences, ensuring that homeowners can select a suitable option that aligns with their needs.

Benefits of Choosing Standing Seam Metal Roofs

Opting for standing seam metal roofs over traditional roofing materials presents numerous advantages that are noteworthy. These benefits include:

- Longevity: Standing seam metal roofs typically last 40 to 70 years, significantly outpacing many conventional roofing materials like asphalt shingles, which often require replacement every 20 years.

- Low Maintenance: The absence of exposed fasteners reduces the risk of leaks, minimising maintenance requirements over the roof’s lifecycle.

- Energy Efficiency: Metal roofs reflect solar radiant heat, which can reduce cooling costs in warmer climates.

- Environmental Sustainability: Many metal roofing materials are made from recycled content and are fully recyclable at the end of their lifespan, making them an eco-friendly choice.

Standing seam metal roofs combine aesthetic appeal with functionality, providing a modern solution that stands the test of time.

When considering roofing options, the advantages of standing seam metal roofs highlight their increasing popularity among homeowners and builders alike, establishing them as a forward-thinking choice in modern architecture.

Installation Process: Standing Seam Metal Roof

The installation of standing seam metal roofs is a meticulous process that demands both precision and the right tools. Following a step-by-step approach not only enhances the longevity of the roof but also ensures its performance under diverse weather conditions. Each stage of the installation process plays a crucial role in achieving a flawless finish.

The installation process generally involves several key stages, from preparation to the actual assembly of the roof panels. Each stage requires specific tools and equipment to facilitate a successful installation. This section will Artikel the systematic approach to fitting a standing seam metal roof along with the necessary resources and common challenges that may arise.

Step-by-Step Installation Process

The steps Artikeld below provide a comprehensive guide to installing a standing seam metal roof:

- Site Preparation: Clear the roof surface of any debris and ensure the structural integrity of the underlying framework. This may include reinforcing weak spots.

- Underlayment Installation: Lay down a high-quality underlayment that provides water resistance, protecting the roof decking from moisture.

- Installation of Furring Strips: Install furring strips perpendicular to the roof slope to provide a solid base for the metal panels.

- Panel Layout: Begin by measuring and marking the layout of the panels, ensuring they align correctly with the building’s edge.

- Panel Cutting: Use a metal shear to cut the panels to the required lengths, ensuring no sharp edges are left exposed.

- Panel Attachment: Lift the panels onto the furring strips and secure them with clips, ensuring a snug fit that allows for thermal expansion.

- Seaming: Use a mechanical seamer to lock the panels together at the seams, which forms a weather-tight barrier.

- Flashing Installation: Install flashing around roof penetrations and edges to prevent water intrusion.

- Final Inspection: Conduct a thorough inspection to ensure all panels are secured correctly, and check for any areas that require additional sealing or adjustments.

Tools and Equipment

Utilising the right tools and equipment is paramount for the successful installation of standing seam metal roofs. The following list details essential tools that should be at hand:

“Quality tools lead to high-quality workmanship.”

- Metal Shears: For cutting metal panels accurately and safely.

- Drill and Screwdriver: Essential for securing panels and other components together.

- Seaming Tool: A mechanical seamer is crucial for locking panels together at the seams.

- Measuring Tape: For precise measurements during the layout and cutting process.

- Safety Gear: This includes helmets, gloves, and goggles to ensure the safety of workers during installation.

- Ladder or Scaffolding: For safe access to all areas of the roof during installation.

Common Challenges and Solutions, Standing seam metal roof

Despite careful planning, various challenges can arise during the installation of standing seam metal roofs. Recognising these potential issues and having solutions ready can mitigate delays and ensure a successful installation.

One common challenge involves dealing with irregular roof shapes. To overcome this, careful planning and custom cutting of panels may be necessary. Ensuring that measurements are taken accurately can prevent misalignments that could lead to leaks.

Another issue is improper sealing at the seams, which can lead to water penetration. Employing a mechanical seamer correctly and double-checking the integrity of the seams during installation can help prevent this.

Weather conditions can also pose challenges; high winds or rain can hinder installation. Planning the installation for favourable weather days and having tarpaulins ready for unexpected rain can safeguard the project.

Lastly, the use of substandard materials can lead to premature wear and failure of the roof. It is vital to select high-quality metals and components that comply with industry standards to ensure durability and performance.

Maintenance and Longevity

The maintenance and longevity of standing seam metal roofs are critical considerations for homeowners and building managers alike. Proper care not only extends the lifespan of the roof but also preserves its aesthetic appeal and functionality. This discussion details an effective maintenance schedule, explores factors influencing lifespan, and highlights common repairs necessary to ensure these roofs remain in optimal condition.

Detailed Maintenance Schedule

Establishing a routine maintenance schedule is essential to prolonging the life of a standing seam metal roof. Regular inspections and maintenance tasks can prevent minor issues from escalating into significant problems. Below is a recommended maintenance schedule:

- Bi-Annual Inspections: Conduct thorough inspections in spring and autumn to assess the roof’s overall condition, checking for signs of wear such as rust, scratches, or loose seams.

- Clearing Debris: Regularly remove leaves, branches, and other debris from the roof surface and gutters to prevent water pooling and blockages.

- Sealant Inspection: Inspect sealant around joints and seams every two years. Reapply as necessary to maintain water resistance.

- Cleaning: Wash the roof with a mild detergent and water every two to three years to remove dirt and prevent corrosion.

- Professional Inspections: Hire a professional roofing expert every five years for a comprehensive assessment, including checking for structural integrity and potential issues not visible to the untrained eye.

Factors Influencing Lifespan

Several factors contribute to the overall lifespan of standing seam metal roofing systems. Understanding these influences can guide proper installation and maintenance practices, ensuring maximum longevity.

- Material Quality: The quality of the metal used, such as Galvalume or aluminium, significantly affects durability. Higher-grade materials are less prone to corrosion and weathering.

- Environmental Conditions: Roofs exposed to harsh weather conditions, including extreme temperatures, heavy rainfall, or salt water, may experience accelerated wear. In coastal areas, for example, the saline atmosphere can lead to faster corrosion.

- Installation Quality: Proper installation by experienced professionals ensures that seams and joints are watertight, reducing the risk of leaks and structural issues.

- Maintenance Practices: Regular upkeep, as Artikeld in the maintenance schedule, plays a vital role in extending the roof’s lifespan. Neglect can lead to premature deterioration.

Common Repairs and Handling

Even with diligent maintenance, standing seam metal roofs may require repairs over time. Understanding common issues and effective repair methods is essential for homeowners.

- Punctures or Dents: Minor damage can often be repaired by cleaning the affected area, applying a matching touch-up paint, and sealing any exposed metal to prevent rust.

- Loose Seams: If seams become loose, they can be re-tightened and resealed to restore watertight integrity. It is crucial to use compatible sealants for metal roofs.

- Rust Spot Treatment: Small rust spots can be sanded down, treated with a rust-inhibiting primer, and then painted with a matching finish to prevent further corrosion.

- Flashing Repair: Damaged flashing should be replaced immediately to avoid leaks. Properly fitted new flashing can enhance water drainage and overall roof performance.

“Regular maintenance and prompt repairs are key to ensuring the longevity and performance of standing seam metal roofs.”

Cost Considerations

The financial implications of installing a standing seam metal roof extend beyond mere initial outlay; they encompass a broader perspective of long-term savings and return on investment. Understanding these cost considerations is vital for homeowners and builders alike, as they navigate the complexities of roofing options.

The initial cost of a standing seam metal roof is typically higher than traditional roofing materials, such as asphalt shingles. However, this upfront investment can lead to significant savings over time due to the roof’s durability, energy efficiency, and minimal maintenance requirements. Homeowners often find that the longevity of metal roofs—often exceeding 50 years—means fewer replacements and repairs, ultimately resulting in lower lifetime costs.

Cost Analysis

A comprehensive breakdown of costs associated with standing seam metal roofs is essential for informed decision-making. Below is a detailed examination of the various financial aspects, including materials, labour, and maintenance.

| Item | Estimated Cost (£) | Notes |

|---|---|---|

| Materials | £60 – £120 per square metre | Includes panels, fasteners, and underlayment; prices vary based on material quality. |

| Labour | £40 – £70 per hour | Professional installation is recommended for optimal performance and warranty validation. |

| Maintenance | £100 – £300 per year | Regular inspections and cleaning, though less frequent than traditional roofs. |

In addition to understanding immediate costs, financing options and incentives available for metal roofing installations can further alleviate the financial burden.

Many local governments and utility companies offer grants, tax credits, or rebates to encourage the adoption of energy-efficient roofing systems, including standing seam metal roofs. These financial incentives can significantly offset initial expenses and make this sustainable solution more accessible. Homeowners may also consider financing options such as low-interest loans or payment plans, which can help bridge the gap between initial expenditure and long-term savings.

“Investing in a standing seam metal roof not only enhances the aesthetic appeal of a property but also represents a strategic financial decision with substantial long-term benefits.”

When discussing the risks associated with older buildings, it’s imperative to identify asbestos containing material , which can pose significant health hazards. To better understand why it is dangerous, one must first grasp the asbestos definition , detailing its fibrous nature and historical use in construction. Awareness of these factors is crucial for ensuring safety in renovation projects.

Understanding the implications of asbestos definition is essential for anyone involved in property management. Particularly, the focus should be on asbestos containing material , which may still be present in many older structures. Identifying these materials can prevent severe health issues, thus highlighting the importance of thorough inspections and awareness.